|

-

28th July 08, 08:42 AM

#1

First X-Kilt, in camo

Found this nice mid-weight, 60" camo in what seems to be poly/cotton blend for $3/yard at a local fabric store. It was in pre-cut lengths of mostly 1-2 yards but hunting through the stacks unearthed a 3+ yard length. I've hand-sewn a kilt from double-wide tartan so I figured I could join two lengths in similar fashion for the X-Kilt.

I didn't take a lot of pics of layout and construction where it conforms to X-Kilt instructions (boring, and the flash really bounces off this fabric). But here are a few detail shots of the joining, and of one point where I discovered a glitch in the X-Kilt manual. Take heed, if you haven't made one yet!

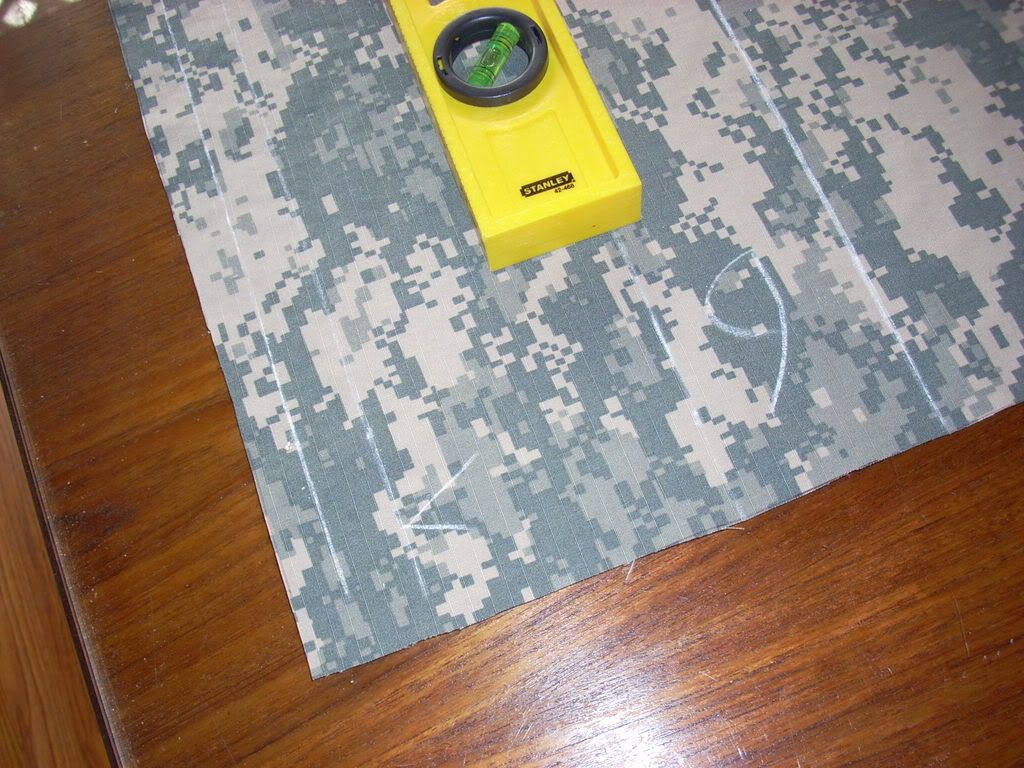

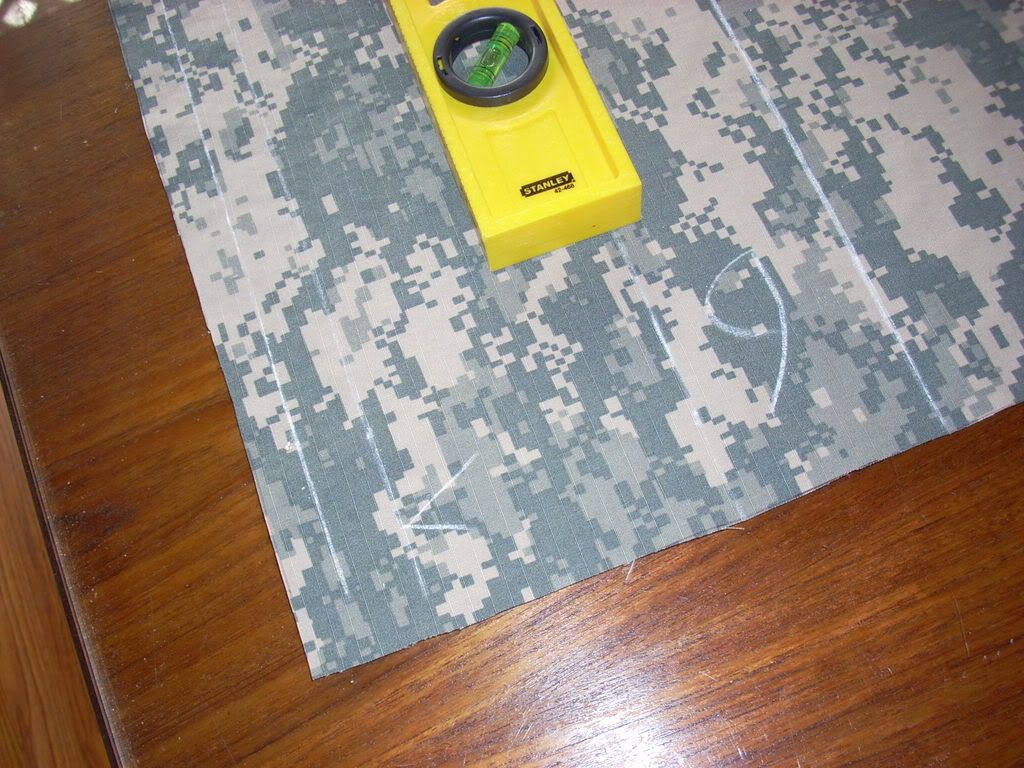

I needed 12 pleats. Laid out the chalk lines on first cut of fabric and got to the leading edge of pleat #10 (photo shows pleat #9 and "box" between 9 and 10). Backed off one inch from the leading edge of #10 and chalked a line for the seam.

Took up my second cut of fabric, chalked a line 1 inch from edge for seam allowance, one inch for the remainder of the box, then continued with pleats 10, 11 and so on.

Sewed the seam and pressed it open. This shows the right side (seam is at the chalked arrow mark).

Here's the wrong side, seam allowances pressed open and one side trimmed to about 1/4 inch in prep for a finished technique that will prevent this seam ever fraying. Here, I've trimmed the side that is next to pleat #10 but I strongly recommend trimming the other edge, the one that is AWAY from the nearest pleat (I'll explain why later).

Fold about half the untrimmed seam allowance in toward the seam and press it down.

Then fold that toward the trimmed edge, so the folded edge completely captures the trimmed edge. All your seam allowance material is now on one side of the stitched seam line -- here, the seam is on the left and the folded material is to the right.

Sew along the folded edge. This puts a line of "bobbin side" stitching on the right side of the kilt, but it will be hidden inside the fold between pleats 9 and 10.

Finished seam, from the right side of fabric. Chalk arrow shows the seam, stitched line is to the left of it. As I said, you should do the opposite -- fold the allowances AWAY from the closer pleat 10. When top-stitching the outer edge of pleat 10, the folded seam allowance was just a tad too close, and interfered with my top-stitch line (nudged the edge of the presser foot).

More to come. . .

-

-

28th July 08, 08:44 AM

#2

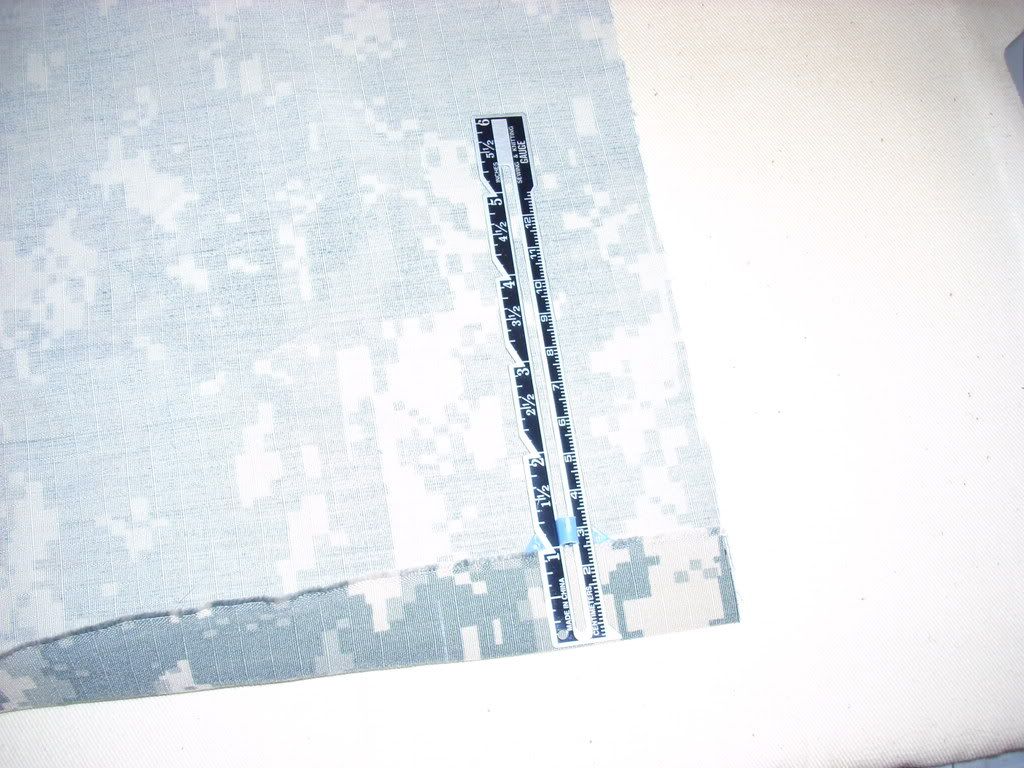

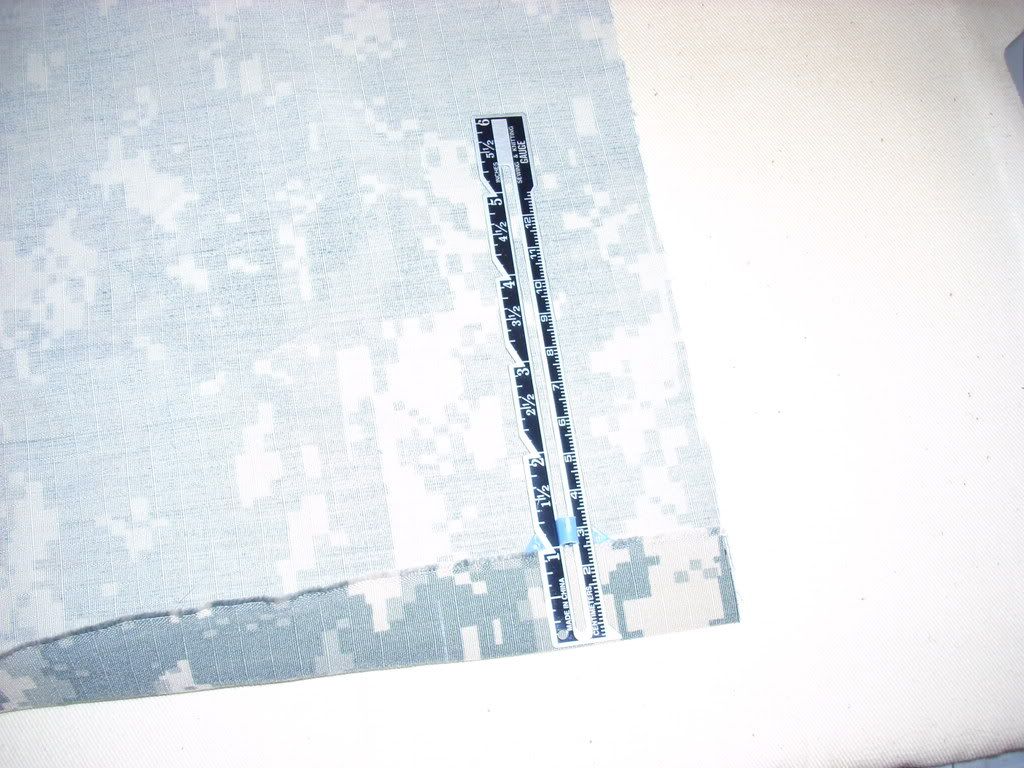

Now that the fabric is joined, I can hem the lower edge. This little seam gauge is a handy tool, you'll find them for $1 or so on the notions rack of any fabric store (or included in a "starter kit" of sewing notions).

I ran two lines of stitching for the hem. Here I'm sewing the second line, using the left-hand edge of presser foot to establish/maintain even spacing between the two lines.

At the bottom of each outer pleat edge topstitch, I wanted a nicer finish to the line of stitching -- I wanted a single line of stitching that just stops, without a section of reversed stitching to lock the threads. To keep the stitching from coming undone, I pulled the threads through to the INSIDE FOLD of the pleat, then tied a knot and clipped the ends short. Here are the two threads pulled through to the inside fold.

The rest of the construction is going pretty much by the book, except when it came time to establish the big reverse pleat that underlies the front apron. The manual has you putting Velcro strip onto front apron before pleating. . . but then comes the big reverse pleat.

And most of your Velcro would be between the pleat and the front apron, where it can't stick to the underapron. So don't finish the right-hand edge of the front apron and put that Velcro strip on until you are ready to place the waistband! This means not capturing the left-hand edge of the Velcro strip inside the front apron finish -- I think it will be OK just secured along top and right-hand edges. I did stabilize the left-hand edge of Velcro strip, since it won't be captured inside the front apron finish. Thanks to Pleater and 12Stones for their replies to my earlier post on this subject.

http://www.xmarksthescot.com/forum/m...537/index.html

I'm to the point of sewing down inside of waistband, need to stop and make that leather thimble! More pics as I get farther along. . .

-

-

28th July 08, 08:45 AM

#3

Nice lookin' stuff...the finished product should look great and I see that you're well on your way.

Best

AA

-

-

28th July 08, 01:43 PM

#4

I'd like to see the finished kilt when you're done

-

-

28th July 08, 03:10 PM

#5

Done stitching the waistband, have to wait for Bob to get home so I can place second piece of Velcro. Meantime I'll check his Union Kilt for cargo pocket ideas.

Top edge, finished.

On the floor, back view.

Interim resolution of the front apron Velcro. I had to cut the original backing piece out of the front apron finished edges, so I sewed it down to a second, larger backing piece and stabilized all edges. RH edge is machine-sewn to the underside of RH front apron hem, top is sewn into waistband, LH edge is hand-sewn to inside of first pleat LH edge. If this results in some funny front apron/pleat pulling, I'll re-do it -- might end up with some extra stitching showing on the outside, que sera.

-

-

28th July 08, 03:32 PM

#6

-

-

28th July 08, 04:23 PM

#7

Great job! We'll have to start having digi cammo kilt nights when I get my USAF ABU kilt.

-

-

28th July 08, 04:35 PM

#8

I'll be there (in spirit) in my woodland MARPAT.

Can I ask, would you rather have turned the fabric over so the pattern would look more parallel to the ground than up and down? Most camo prints come this way as it's easier to manufacture but the pattern just doesn't look right to me when cut that way.

-

-

28th July 08, 05:07 PM

#9

Originally Posted by OFCJAX

I'll be there (in spirit) in my woodland MARPAT.

Can I ask, would you rather have turned the fabric over so the pattern would look more parallel to the ground than up and down? Most camo prints come this way as it's easier to manufacture but the pattern just doesn't look right to me when cut that way.

Never even thought of doing that, and it would have meant a seam every 60 inches (or whatever fell into pleat pattern).

On this particular fabric, there's another twist. You can just see faint white lines running from selvedge to selvedge. Unfortunately they don't run straight  perhaps why it was on the remnants table! Not so noticeable when they are going up/down on the pleated kilt, as lots of other things run at an angle (A-line of apron, taper of pleats, etc.) but maybe very noticeable if I had tried to run them horizontal. But that's just this fabric. perhaps why it was on the remnants table! Not so noticeable when they are going up/down on the pleated kilt, as lots of other things run at an angle (A-line of apron, taper of pleats, etc.) but maybe very noticeable if I had tried to run them horizontal. But that's just this fabric.

Tell you what, you do one parallel to ground and show us how it looks

Currently negotiating construction of cargo pockets with the end-user; will report back later.

-

-

28th July 08, 06:31 PM

#10

-

Similar Threads

-

By Mipi in forum Kilt Advice

Replies: 16

Last Post: 27th May 08, 01:34 AM

-

By Brian F in forum DIY Showroom

Replies: 10

Last Post: 24th October 07, 06:40 AM

-

By ScottInNewHampshire in forum General Kilt Talk

Replies: 23

Last Post: 3rd April 07, 08:50 PM

-

By O'Neille in forum General Kilt Talk

Replies: 3

Last Post: 27th August 06, 05:48 PM

-

By Miah in forum How to Accessorize your Kilt

Replies: 3

Last Post: 21st July 04, 11:49 AM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks