|

-

16th July 09, 08:58 PM

#1

it quacks like a kilt

Inspired by the recent discussion of duck cloth x-kilts, I noticed that my local fabric store had #12 duck on sale, for 3.75 a yard. I got four yards of 72" wide, unbleached, undyed stuff. I washed and dryed it a couple times, and it shrank quite a lot (5% width, about 10% length.). I had some time this evening, so I started working on it. Because of the greater shrinkage warp-wise, and it shrank in the second wash cycle, i decided I work with the length of the fabric running vertically. That necessitates cutting out pieces that are the length you want (plus a bottom hem, plus a bit for safety at the top.) In my case, I cut 26", aiming for a finished length of 24".

When I did the red corduroy kilt, I stiched the various lengths of fabric together, and then put pleats in it. Dealing with a 24 foot long piece of corduroy wasn't much fun, so I decided I do it the other way around: put the pleats in the fabric, and then join the pieces. One seam is in the center back, the other two will be just beyond the aprons. those side seams will allow for nearly invisible pockets in front.

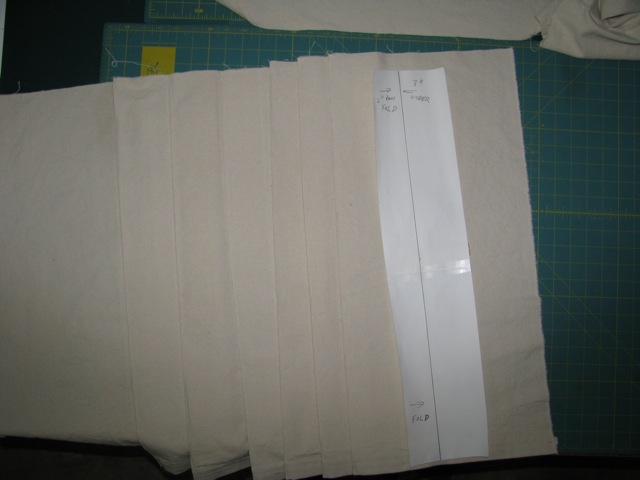

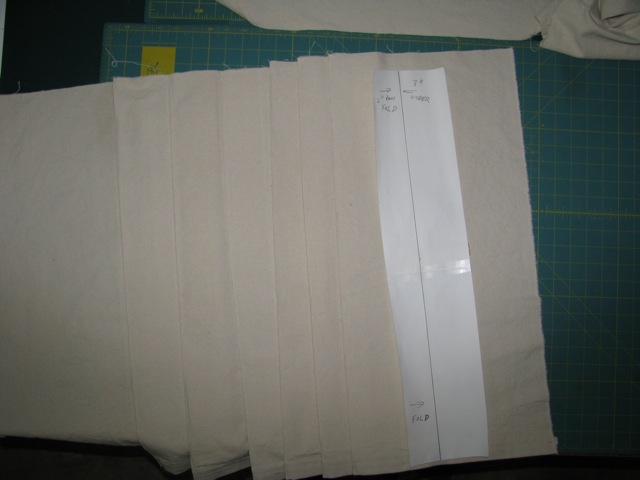

I only got the two rear pieces cut, hemmed, pleated, and pleats stiched in, (I need a faster machine!) and the two pieces joined together. (I need an overlock machine. Felled seams in #12 duck are lumpy.) A couple pictures showing the use of the cardboard folding jig I use to make the pleats:

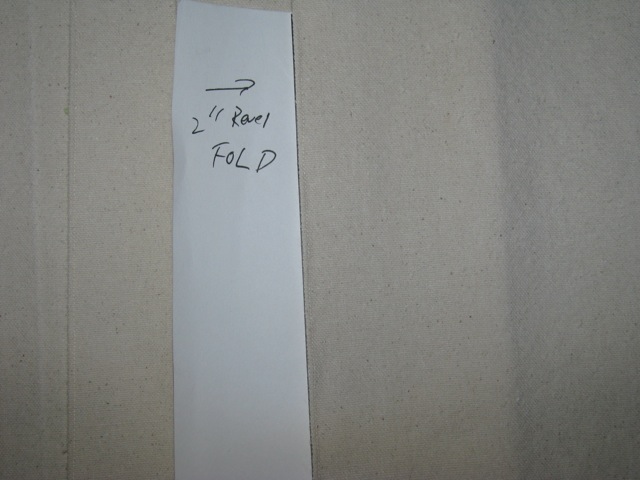

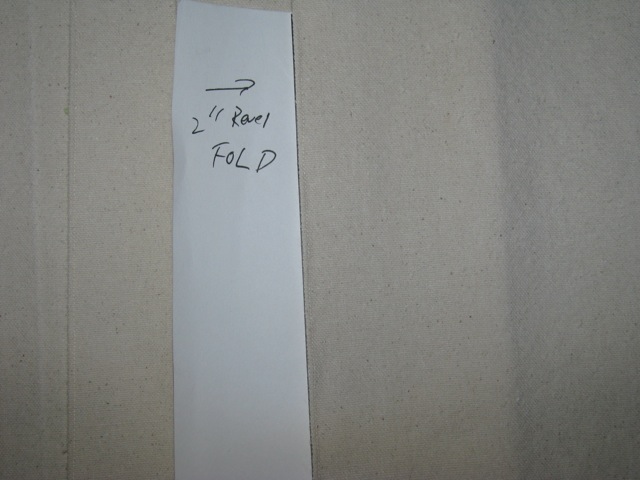

It's just a piece of tag stock (the stuff manilla folders are made of. I use white, instead of buff, because I can see it better, and the writing is easier to read) cut to the width of (depth of pleat + reveal of pleat), with a line drawn at the fold (and labeled "Fold!"). the two halves are also labeled, including the measurement. To use it, you put the reveal side on the edge of the previous pleat, and fold the fabric over the under side to the fold line. Make sure it's even, then press hard, with steam. Repeat. I knocked out the six pleats on each half in about five minutes, including time waiting for the iron to heat back up. You could pin, but pressing is faster, easier, and more accurate. Doing the pleats by actually measuring them takes quite a bit longer.

That's for knife pleats (I'm doing a Rev-K kilt); if you're doing box pleats, like the bog-standard X kilt, you can use a pair of jigs, one for the bottom of the box, and the other for the top.

-

-

16th July 09, 09:35 PM

#2

Interesting... Pleating jigs.

These types of kilts are becoming interesting to me again. I'm in the middle of overhalling my kilt that is made of army duck, or something like that. It's all hand sewing for me though.

Are you edge stitching each pleat?

I tried to ask my inner curmudgeon before posting, but he sprayed me with the garden hose…

Yes, I have squirrels in my brain…

-

-

16th July 09, 10:10 PM

#3

Smart way of handling the pleating...jigs...

Uilleam 'Wolfhawk' Kerr

(William 'Hawk' Bennett)

Queen's Own Highlanders * Queen's Royal Highlander Guards * The Order of Culloden Moor

Na Fir Dileas * IBRSC #1654 * RMG #921 * Assassin Guild * RenRat Nation

-

-

17th July 09, 01:47 PM

#4

A pleating jig? A pleating jig?!! A PLEATING JIG!!! Wow! That's a real "why didn't I think of that?" moment.

By the gods, my next kilt will be a hell of a lot easier to pleat. The only pleats I'll have to really watch are the ones where I need to put in taper. Thanks!

-

-

17th July 09, 09:33 PM

#5

Originally Posted by Erisianmonkey

A pleating jig? A pleating jig?!! A PLEATING JIG!!! Wow! That's a real "why didn't I think of that?" moment.

By the gods, my next kilt will be a hell of a lot easier to pleat.

Yes. It's much easier. I'm sort of embarrassed that I didn't think of doing it before.

didn't get much done tonight. Cut out the piece for the left front and over apron, and sewed the pleats in. I'm doing four pleats, with the last one entirely under the apron, and I screwed up the order of sewing those two down. (sew the one hidden by the other one first. duh.) I discovered that picking out the stitches requires undoing nearly every single one, and as I can barely see them, it took 40 minutes to do 9 inches of stitching. Stupid high-quality thread. I did make the folding jig for the welt pockets.

-

-

18th July 09, 08:52 AM

#6

Originally Posted by vorpallemur

[snip, so to speak] I discovered that picking out the stitches requires undoing nearly every single one, and as I can barely see them, it took 40 minutes to do 9 inches of stitching. Stupid high-quality thread. I did make the folding jig for the welt pockets.

A good seam-ripper is your friend -- less than $5 but priceless. If you're careful, and your fabric isn't too delicate, you can insert the point between the two layers of fabric and push -- cutting the thread loops that lie between the layers, in one long motion down the length of the seam. Then use a fingernail to "scratch" the loose thread up from either side, and you're done. Little leftover bits will usually come out in the wash.

Wouldn't advise it for silk, knits, etc. but I use it when needed on denim, poly/cotton bottomweights, etc.

Proudly Duncan [maternal], MacDonald and MacDaniel [paternal].

-

-

18th July 09, 02:20 PM

#7

Originally Posted by sydnie7

A good seam-ripper is your friend -- less than $5 but priceless. If you're careful, and your fabric isn't too delicate, you can insert the point between the two layers of fabric and push -- cutting the thread loops that lie between the layers, in one long motion down the length of the seam. Then use a fingernail to "scratch" the loose thread up from either side, and you're done. Little leftover bits will usually come out in the wash.

Wouldn't advise it for silk, knits, etc. but I use it when needed on denim, poly/cotton bottomweights, etc.

I've got seam rippers, and I'm not afraid of using them. The problem is that the stitches are very tight and the thread is a near perfect match for the fabric, and there are enough loops of fabric yarn on the wrong side that I don't trust myself not to get one using the seam ripper as a knife.

-

-

17th July 09, 01:59 PM

#8

Previously, some clever forum member posted pics of a jig he'd made up for folding double-box pleats. Now that was a jig to dance to LOL

Proudly Duncan [maternal], MacDonald and MacDaniel [paternal].

-

-

17th July 09, 03:25 PM

#9

Originally Posted by sydnie7

Previously, some clever forum member posted pics of a jig he'd made up for folding double-box pleats. Now that was a jig to dance to LOL

I am gonna have to search for that cause I am wanting to do a double box pleat eventually LOL

-

-

18th July 09, 02:35 PM

#10

Don't know if it matters, but I've often used a knife that has been sharpened in a certain way to cut tight stitches. It's sharpend without removing all the tiny, tiny serarations made by the stone, and it almost saws through the stiche. So I stick the point between the stitches, pull the seam apart a little, then move the knife just a little. It saws the stich on a very small scale, if that makes sense.

I tried to ask my inner curmudgeon before posting, but he sprayed me with the garden hose…

Yes, I have squirrels in my brain…

-

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks