|

-

20th July 13, 03:11 PM

#1

Poor Quality HAND SEWN kilt

Hey guys,

A bit of history... Those of you who know me and have heard my 'pitch' may have heard me answer the question (which is asked a LOT), "Which is better... a Hand Sewn kilt or a Machine Sewn kilt?" My answer is ALWAYS, "it depends on the skills of the kiltmaker... I've seen high quality hand sewn kilts and POOR quality hand sewn kilt just like I've seen high quality machine sewn kilts and POOR quality machine sewn kilts".

A while back I posted a thread (http://www.xmarksthescot.com/forum/f...ys-kilt-78079/) about the insides of one of our competitor kilts. It was a poorly made machine sewn kilt.

Today, a pipe band who uses us for a few items called about bringing in a couple kilts to be repaired and altered. NORMALLY we do not repair other kilt maker's work because we don't know what we'll find (you'll understand why by the end of this post), but since these 2 individuals are existing customers and have purchased MULTIPLE kilts from us, we wanted to help them out. Below is an example of a poor quality hand sewn kilt, as brought in by a local band who went with a reasonably inexpensive, local, part time kilt maker (in MD). She isn't new to the trade... her website states that she's been making kilts for 38 years.

I am specifically NOT naming the company used to make this kilt (b/c I don't want to embarrass them in public), but if you'd like to see the "signature" on the inside of the kilt to verify who I am speaking about, I will gladly email you a picture.

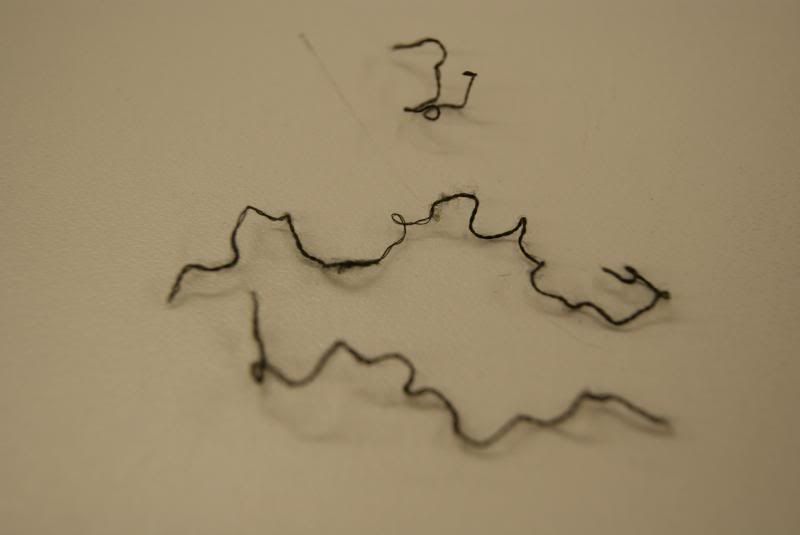

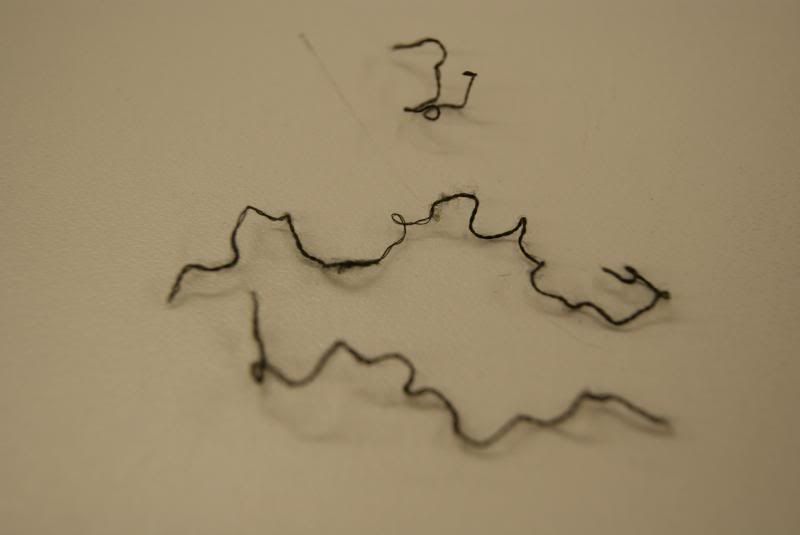

Ron Macdonald (Riverkilt) has posted multiple times about the quality of thread being an issue when sewing a kilt. I COMPLETELY agree and now can show you why. When you use poor quality and reasonably thin cotton thread, it will deteriorate over time. The kilts I repaired today were made in 2008 and 2010. The wool fabric itself was still in FANTASTIC shape (which tells me the kilts weren't abused or excessively dry cleaned to cause premature deterioration of the thread). Here is some of the thread that was pulled from the kilt where the thread had snapped. Notice how fuzzy the thread is and how there are thin spots visible where it would have failed again:

I did do a burn test on this thread. When burned, the smoke was not black and ashed up and kept burning until I blew it out. It left ashes and not a hard plastic ball. It smelled like smoke and not burning hair, so I determined it to likely be cotton.

Another issue with this particular kilt (which will be compounded by brittle disintegrating thread) is the stitches per inch. A good hand sewn kilt will have 8 to 10 stitches per inch. More stitches per inch = more time it takes to sew. That's the beauty of a machine sewn kilt... you set the stitches per inch by a dial on the machine and it doesn't take any longer or shorter. On a hand sewn kilt, each stitch takes time, and time = money.

This particular kilt has 5 stitches per inch (and I sampled the kilt across 10 pleats with my ruler to get a fair average # of stitches per inch). I used pins to show the location of each stitch, to make it easier to see:

The ISSUE with fewer stitches per inch is that there is more stress ("load") born by each stitch when the body pushes out against the fabric. This is ESPECIALLY true when the canvas lining isn't sewn in (see next section). When you couple the additional stress of fewer stitches with the poor quality thread, you get breaks in the thread. This kilt also doesn't appear to have any "lock stitches", meaning that if a thread fails (breaks), it will pull out to a locked stitch and STOP. Here are 2 pleats that have torn out due to failed stitches:

Here is a stitch that JUST failed and is starting to come apart:

On top of the thread issue, this kilt also has fusible lining ironed in, instead of horsehair canvas lining sewn in. Fusible lining is used by some large machine sewn kiltmakers in Scotland to save time, but I have NEVER seen it in a hand sewn kilt before. It saves roughly 30 to 40 minutes of labor in the makeup, but over time, the fusing glue comes loose and presto, the internal lining is just 'floating' under the cotton lining, serving no purpose. This puts ALL the stress on the pleat stitches, and where there are only 5 stitches per inch, you get failed stitches (breaks).

You'll also notice in the picture above that the scalloped pleats are not all sewn together (steeked). Well, funny thing... they WERE steeked, but the thread snapped, leaving 3/4 of them 'dangling' without any reinforcement from steeking stitches OR the reinforcement of a horsehair canvas (since the fusible interfacing had come unglued). This contributes to pleat 'splay' and having the depth of each pleat stick down below the bottom of the selvedge.

The stitches holding the bottom of the cotton lining to the wool also failed (again, cheap thread):

The black bar in the above photo covers up the kiltmakers signature and date (she signs and dates each kilt she makes).

I wanted to hold this kilt up as an example that no matter hand sewn VS. machine sewn, no matter 1 year making kilts VS. 38 years, there are good and bad quality kilts out there.

A quality kilt is made up of a combination of ALL of the following:

1. Quality material

2. Quality thread and internal components

3. Skill of the kilt maker

I hope this helps to explain more of what to look for in a kilt and helps to educate a bit about the construction of a proper kilt.

Last edited by RockyR; 20th July 13 at 03:42 PM.

-

The Following 16 Users say 'Aye' to RockyR For This Useful Post:

artificer,Aspiringloser,BCAC,California Highlander,creagdhubh,Dale Seago,Grizzled Ian,Hawk,Kiltedjohn,mookien,Nile,Panache,Peter Crowe,TheOfficialBren,unixken,xman

-

20th July 13, 03:21 PM

#2

Rocky, thank you for pointing this out. I have a couple of questions:

1) do you line all of your wool kilts whether machine or hand-sewn and

2) will you kindly send me the maker's label photo via private message?

Thank you, sir.

The Official [BREN]

-

-

20th July 13, 03:51 PM

#3

We don't make hand sewn kilts, but we can have them made in Scotland for our customers. Yes, THEY are lined properly.

Our machine sewn kilts are lined with horsehair canvas lining. Here's a link to the 'guts' of our kilts in another post:

http://www.xmarksthescot.com/forum/f...so-much-79411/

Our 5 Yard Wool kilts are lined, but DO NOT have the horsehair canvas. They don't need it as the pleats aren't cut out, so they don't need the reinforcement like an 8 yarder does, but they do have a cotton lining to help with the 'load'.

If you email me, I can send you the pic of the inside of this kilt. rocky@usakilts.com

Last edited by RockyR; 20th July 13 at 03:52 PM.

-

-

20th July 13, 06:31 PM

#4

Great pics. Quality kiltmakers are so rare - and even kiltmakers are rare - so when a newbie finds one they are grateful and trusting. One reason I stick tight to the quality kiltmakers I know - Rocky, Robert, and Kathy.

Ol' Macdonald himself, a proud son of Skye and Cape Breton Island

Lifetime Member STA. Two time winner of Utilikiltarian of the Month.

"I'll have a kilt please, a nice hand sewn tartan, 16 ounce Strome. Oh, and a sporran on the side, with a strap please."

-

-

20th July 13, 07:20 PM

#5

Thanks for the info, and pictures. I'm suprised as well, as I believe I know the maker.

[snip] ...but over time, the fusing glue comes loose and presto, the internal lining is just 'floating' under the cotton lining, serving no purpose. [/snip]

My drycleaner loves fusable interfacing. He admitted to me, it's a great money maker. Well... after he rips apart a garment and puts it back together. Cha-ching

-

-

21st July 13, 03:10 AM

#6

Let me just say, as a kilt maker who occasionally takes in repair work (please don't bombard me with repair requests, like Rocky, I stay busy enough making kilts and really only do it as a favor to customers), I too have come across the same scenarios, having to repair very poorly made kilts.

I even took photos of one that I thought particularly bad, thinking to do a photo essay of "what not to do" but never got around to it. But it was a lot of the same faults as Rocky finds here. This is not an isolated occurrence.

-

-

21st July 13, 08:31 PM

#7

Oops! I sent the same email twice. Kindly disregard today's message, Rocky. It was pertaining to this post. I thought I didn't send the first one and accidentally resent it again. Thank you.

The Official [BREN]

-

-

22nd July 13, 02:04 AM

#8

Good instructive thread, Rocky. A good eye-opener. Thanks for posting.

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks