|

-

20th August 15, 03:40 PM

#11

Making an argyle pattern is probably best done on a Japanese domestic knitting machine.

first you knit some triangles /\ /\ /\

rather than decreasing stitches they are removed onto hand knitting circular needles.

Then you replace stitches from the sides of two triangles and knit the in between \/ \/ \/ so joining them into a band. Remove the last row of stitches of as many triangles as necessary so as not to stretch the knitting - it being made into a continuous loop just over half of the circumference has to be removed from the machine, the rest can be left with the needles in holding position.

The knitting is probably best done with an intarsia carriage so as to enable the single stitch diagonal lines to be knitted in.

Triangles to complete the tops of the diamonds are then made one by one either putting needles back into work and then removing them onto the circular needles or replacing sets of stitches onto the machine needles and then removing them one by one onto the circular needles.

It would be quite fiddly and you'd need multiple smallish balls of yarn - but quite interesting to achieve something so complex.

Anne the Pleater :ootd:

I presume to dictate to no man what he shall eat or drink or wherewithal he shall be clothed."

-- The Hon. Stuart Ruaidri Erskine, The Kilt & How to Wear It, 1901.

-

-

20th August 15, 05:07 PM

#12

Hi Anne,

Yea, that is how it is done on a flat bed machine. Mine is a Passap E6000.

But I really need to practice more on my circular machine. It is so much easier. I have capability of 6 different colors in work at the same time and I don't ever need to transfer stitches off the machine onto hand knitting needles.

On a circular machine you simply raise the needles to make them idle. What is on them just sits there till you need it.

On a circular machine we knit in triangles. Then fill in between them. The process is actually quite simple I just need more practice to make a perfect sock.

-

The Following User Says 'Aye' to Steve Ashton For This Useful Post:

-

20th August 15, 05:23 PM

#13

Originally Posted by Steve Ashton

*snip* I just need more practice to make a perfect sock.

And I may be lining up, Steve!

Rev'd Father Bill White: Mostly retired Parish Priest & former Elementary Headmaster. Lover of God, dogs, most people, joy, tradition, humour & clarity. Legion Padre, theologian, teacher, philosopher, linguist, encourager of hearts & souls & a firm believer in dignity, decency, & duty. A proud Canadian Sinclair with solid Welsh and other heritage.

-

-

20th August 15, 07:00 PM

#14

Originally Posted by Father Bill

And I may be lining up, Steve!

Maybe at the next Kilt Kamp in Victoria (2016?), Steve will have this perfected enough that the participants could get custom made hose as a bonus prize! [KiltedKnome now ducks and runs from cover from The Wizard who will be swinging some of the "heel weights".....]

-

The Following User Says 'Aye' to KiltedKnome For This Useful Post:

-

21st August 15, 10:17 AM

#15

I suspect that the circular sock machine doesn't make it easy to increase stitches to enlarge the circumference of the leg though.

We (husband and myself) do quite a few repairs on the E6000s, plus upgrading them to download from the PC and increase the memory from 8K to 32K.

We have done quite a bit of work on those lines for Passap Canada.

I'm just trying to find all the bits for a Duomatic 80 I agreed to sell without factoring in the time to do that and service 17 Silver Reed machines - plus the amount of dust which the Duomatic has accumulated whilst lying idle for several years.

I do get myself into some fixes.

One of the first lessons in the Duomatic 80 manual is - a sock.

Anne the Pleater :ootd:

I presume to dictate to no man what he shall eat or drink or wherewithal he shall be clothed."

-- The Hon. Stuart Ruaidri Erskine, The Kilt & How to Wear It, 1901.

-

-

21st August 15, 01:12 PM

#16

With Circular Sock Machines, or CSM for short, we alter the circumference the same way you would when hand-knitting. By increasing or decreasing the number of stitches you cast on.

We do this by changing cylinders. I currently have 7 cylinders with between 54 and 84 needles per cylinder. (Some antiques machines had cylinders with up to 120 slots which required smaller gauge needles.)

A 54 needle cylinder will make socks for girls or a man with thin legs.

A Highland Athlete with massive tree truck calves will need the 80 or even the 84 needle cylinder.

I have made socks to fit a 6" ankle and a sock that will easily fit a guy with 21" calves.

As you well know the type of yarn, its composition, twist and diameter will affect the finished sock greatly. With a CSM we just change out cylinders and/or needles and stitch length, as needed to give the finished result.

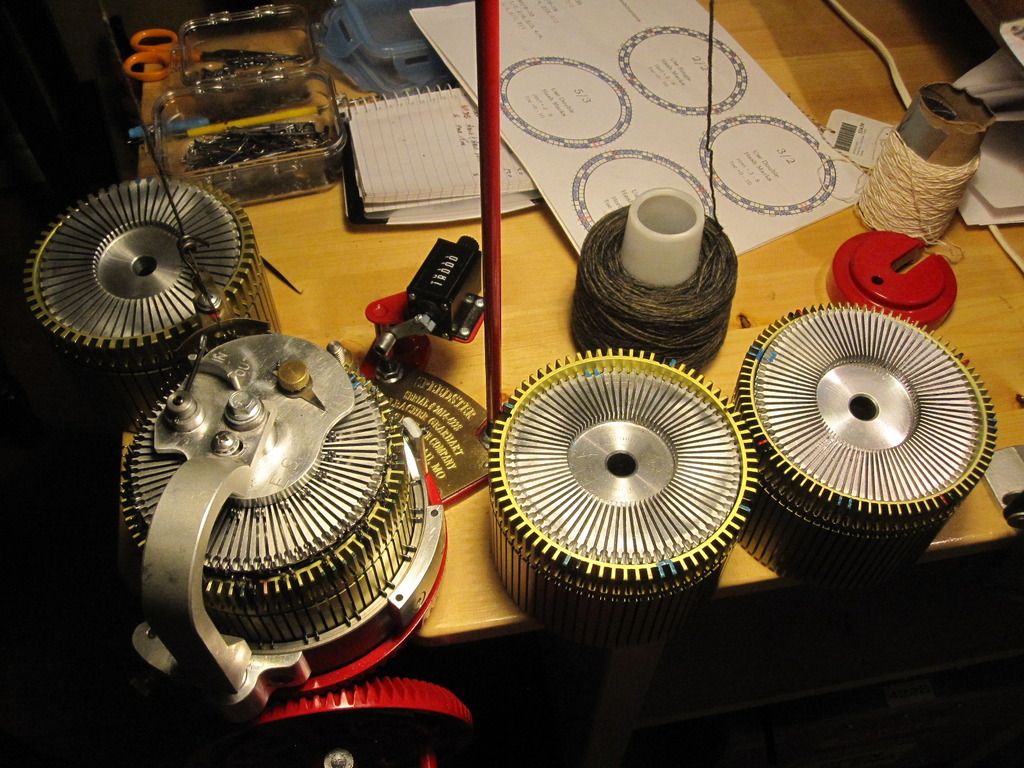

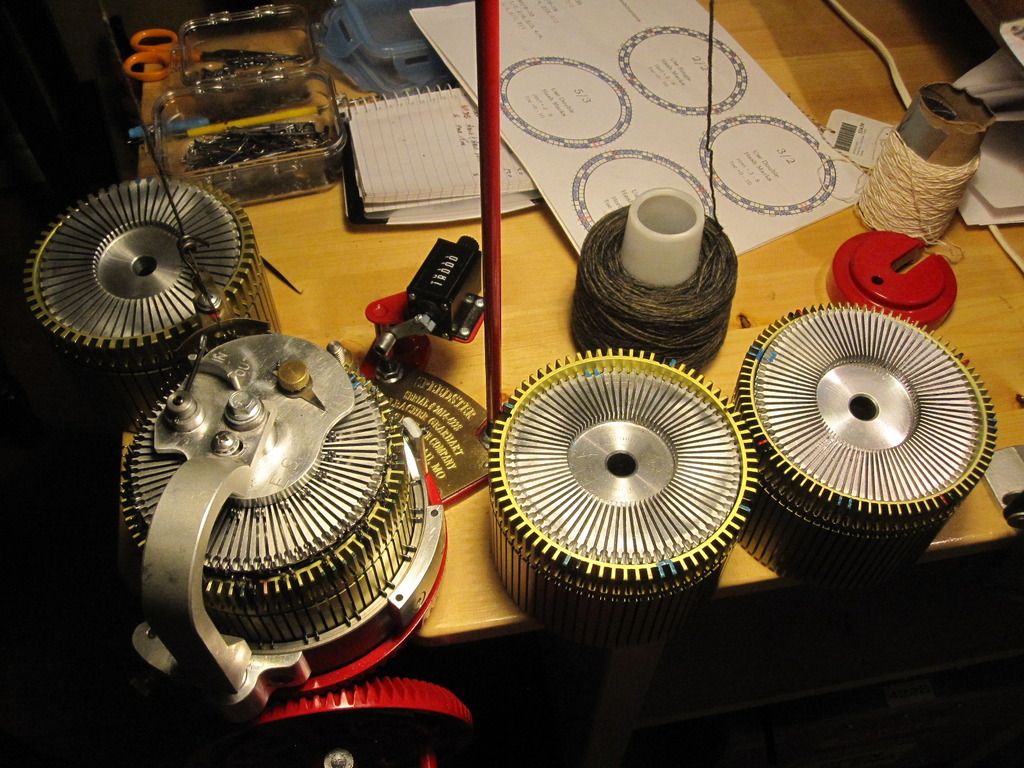

Here are just four of my cylinders. L to R 54 - 72 - 80 - 84.

Last edited by Steve Ashton; 21st August 15 at 01:23 PM.

-

-

21st August 15, 01:37 PM

#17

Do you change the number of stitches in the legs of the hose in order to shape them, or is it the same number of stitches and smaller or larger stitch sizes?

Anne the Pleater :ootd:

I presume to dictate to no man what he shall eat or drink or wherewithal he shall be clothed."

-- The Hon. Stuart Ruaidri Erskine, The Kilt & How to Wear It, 1901.

-

-

21st August 15, 01:40 PM

#18

We can do reductions to form shaping as you would in hand-knitting but I can also change stitch size with the simple turn of a knob. The effect is the same as if you were to change the diameter of hand knitting needles.

-

-

22nd August 15, 11:19 AM

#19

wgnewcomb

Steve : have you made any hose with red dicing yet? If so can I order a pair? Georgie Boy

-

-

22nd August 15, 02:27 PM

#20

I'm not really sure what you mean by red dicing. What is usually meant by that is a narrow band of checks.

Do you mean a narrow band in the cuff part of the sock? If so, no, I have not done checks but have done stripes of different colors like hose toppers.

If you mean what some call diced hose or argyles where there is a diagonal check down the leg than yes, I have done them but I am not yet satisfied with the result enough to sell any. I'm currently working on cables and other fancy treatments to the legs. My next project will be to get back on perfecting Argyles. Hopefully I will have that process down perfect before I head off to a meeting with other sock makers in late September. We call them Crank-ins. I've been asked to teach at this crank-in so need to prepare teaching aids.

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks