|

-

17th April 06, 01:03 PM

#1

The homemade sporran adventure... COMPLETE!

So I've decided to make my own sporran. I'm a silversmith and no mug at most things with my hands but leatherwork is another thing! I've done a few little things here and there: mended a bag, glued a shoe... well not much really. So this will be the ongoing adventures in the try-not-to-awl-my-fingers sporran project.I'm open to advice that's for sure. i'd much rather learn from mistakes I don't have to make, so I'm all ears leathermen/women.

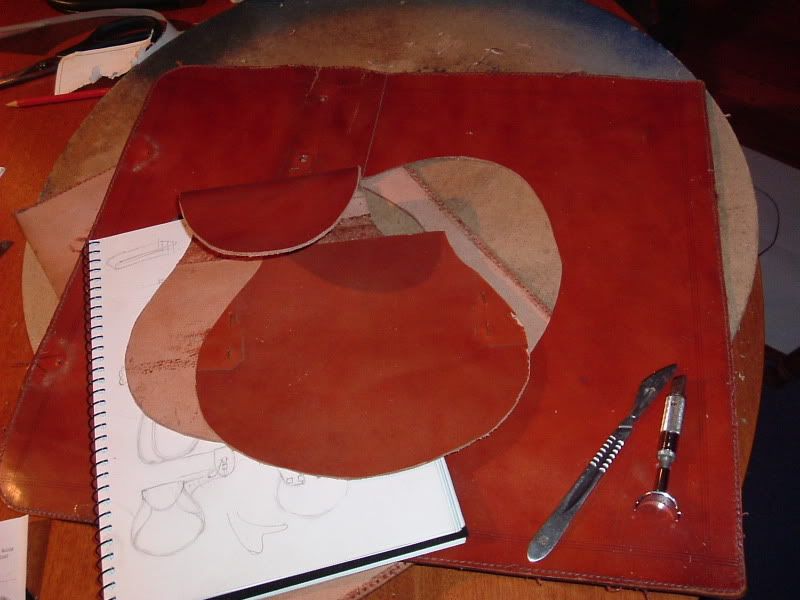

I've started with an old satchel that I've chopped up into it's component bits:

and here's the cut peices:

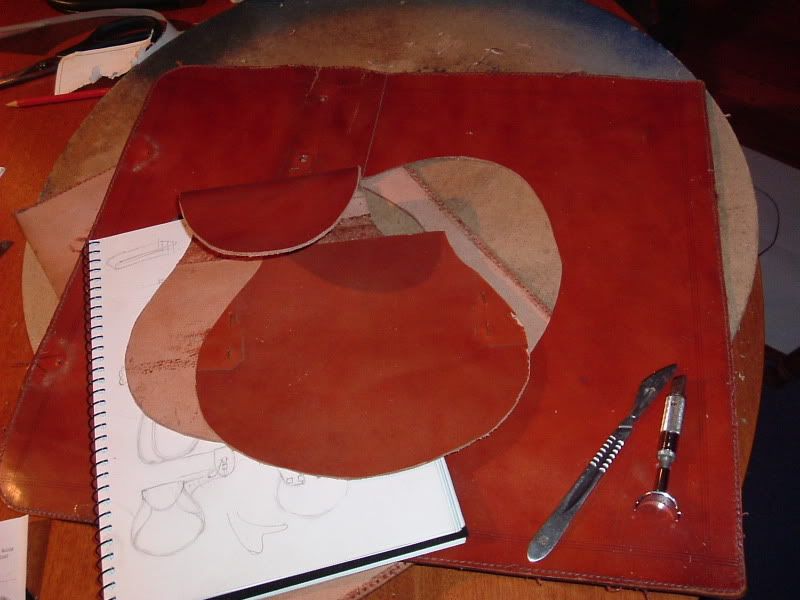

and the semblance of a sporran:

I'll keep you posted.

Last edited by ozmeath; 24th April 06 at 11:04 AM.

Reason: my work here is done.

-

-

17th April 06, 01:13 PM

#2

One caveat to keep in mind:

I am also a leather worker (and metal, including silver smithing) and have several of those exact same cases (dad is a retired USAF Colonel, they are big with officer types) and you will find that most of the material used to manufacture those is in fact a sandwich of very thin leather outer layers, with a cheap cardboard inner layer. The "leather" can tear and rip along the stitch line if you aren't careful, and the layers will come apart as well.

I believe the only portion that is actually solid leather is the top and side flaps and the side gussets.

Best of luck, and kudos for making your own gear!

My Clans: Guthrie, Sinclair, Sutherland, MacRae, McCain-Maclachlan, MacGregor-Petrie, Johnstone, Hamilton, Boyd, MacDonald-Alexander, Patterson, Thompson. Welsh:Edwards, Williams, Jones. Paternal line: Brandenburg/Prussia.

Proud member: SCV/Mech Cav, MOSB.

-

-

17th April 06, 01:14 PM

#3

It looks great! I've been wanting to try that myself! So I'm interested to see what plans and tools etc. you use.

-

-

17th April 06, 01:34 PM

#4

Thanks Mike. you got me to double check the materials and luckily it's all solid leather. It's quite an old one, from the early 70's I can guess.The side piece I'll have to but as there's not quite enough of the thiner leather in it to use. What weight/grade do you recomend Mike?

Matt so far I've basically just used those tools you see there. I did make a 1:1 design on paper. I found the center line, folded it, opened and charcoaled half of the piece and folded again to check symmetry.

I then re-charcoaled it and rubbed it on the leather itself to get an impession to cut out.

that's about it so far.

-

-

17th April 06, 01:37 PM

#5

Sweet! I'm going to go find an old leather briefcase!

-

-

17th April 06, 02:18 PM

#6

Looks good so far. Can't wait to see the final product.

-

-

17th April 06, 02:21 PM

#7

I think my favorite part of the pictures is the drawings you have placed with the work in progress. Good luck, and so far so good.

Glen McGuire

A Life Lived in Fear, Is a Life Half Lived.

-

-

17th April 06, 03:12 PM

#8

Originally Posted by ozmeath

What weight/grade do you recomend Mike?

Glad to hear it's 100% leather, I guess my Dad was cheap when he bought his (We're talking 1960's vintage in my case)! As far as the gusset sides, you could use a 2 to 4 oz lining leather, pigskin, suede, buckskin etc. depending on what's available to you and the final finish you are going for. Any supple, lighter weight leather will do, however since you have a smooth finish on the front and back pieces, you should shoot for something with the scarf skin still intact i.e. vegetable tanned lining leather and not a split, napped, suede finish. Since the pieces you have cut from the case are already stained and finished, it might require a bit of experimentation with the stain and final leather treatment/sheen finish to get a good match. I'd experiment with some scraps of your chosen leather before committing to the finish on the final item.

With this type of Sporran design, it is best to sew the gusset with the outer face against the finished side of the front, then turn it back over the edge toward the rear of the sporran to sew to the back. This will give the rounded, neat looking lip around the front edge and is one of the reasons the gusset piece must be soft and thin enough to do so neatly.

As a fellow silversmith, I know you'll already have many of the skills and craftsmanship to jump right into this without any difficulty. However if you want any help along the way, feel free to let me know as I've made a lot of sporrans over the years.

Last edited by Mike S; 17th April 06 at 03:17 PM.

My Clans: Guthrie, Sinclair, Sutherland, MacRae, McCain-Maclachlan, MacGregor-Petrie, Johnstone, Hamilton, Boyd, MacDonald-Alexander, Patterson, Thompson. Welsh:Edwards, Williams, Jones. Paternal line: Brandenburg/Prussia.

Proud member: SCV/Mech Cav, MOSB.

-

-

18th April 06, 12:14 PM

#9

Many thanks guys, glad you're all along for the ride. Mike that was a good affirmation of the process. Had the same design in mind with the gusseting. Found a suitable weight piece for that, but have to cut it down the middle length-wise as it's wide but not long enough. also it's a bit shinier and slightly darker than the satin/matt finnish of the front/back. I hit it with a no 6 brass suede brush to dull it a little, tho still not quite up to the same patina. the test piece frayed if I went too hard with the brush. also I'm not too sure about the staining. Put a bevelled edge on the flap and front secondary pieces (see pic). The finish is quite sealed so I was of course gonna use test pieces to get the right finish. The front secondary bits are to cover the marks left from the original clasps.

E.

-

-

18th April 06, 12:42 PM

#10

This brings back memories of when Sten Rune and I started. We made our first sporran out of cornflakes packets and bin bags... Looks like your project is comming on well....Have fun

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|

Bookmarks