As some of you may know, I've gotten into the Ren Faire thing. Going to these kilted is so openly accepted that certain types of fun take place... like kilt checks. The mere thought of several women wishing to rub their hands over my bum to determine what's beneath my kilt is quite satisfying.

Anyway... many of the sporrans one can buy off the web simply look too new for ren faire garb (though the Rob Roy style is EXTREMELY popular). I wanted to start doing something that would look cool by todays standards (or at least my somewhat contempo standards anyway), yet looked "patchwork" enough to look good while in garb.

Enter my own sporran making. Along with a budding leatherworking hobby came this new source of enjoyment. So far, I have produced 2 sporrans from $35 worth of 9/10 ounce and 4/5 ounce leather. One of those has been sold for $45. A third one - from the same supply of leather, though slightly smaller than the other 2 - is in the works. The 2nd needs only some sort of closure, then it is indeed done. Oh yeah... I've even given them a "brand name" which is CroMag. he he he

Now... no thread like this would be complete without photos, so I bring you... CroMag Sporran #2 (I never got any photos of #1):

Front:

Back:

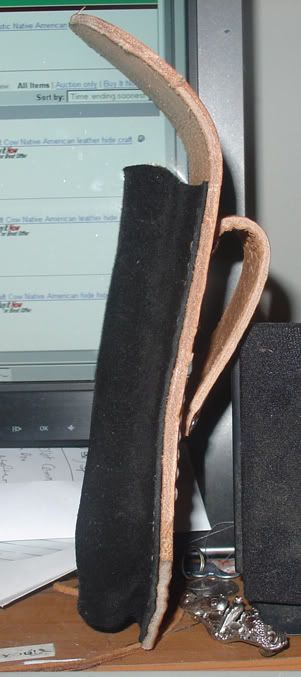

Side (breaking away from what seems to be a conspiracy to hide sporran sides):

Commnets?

Bookmarks