|

-

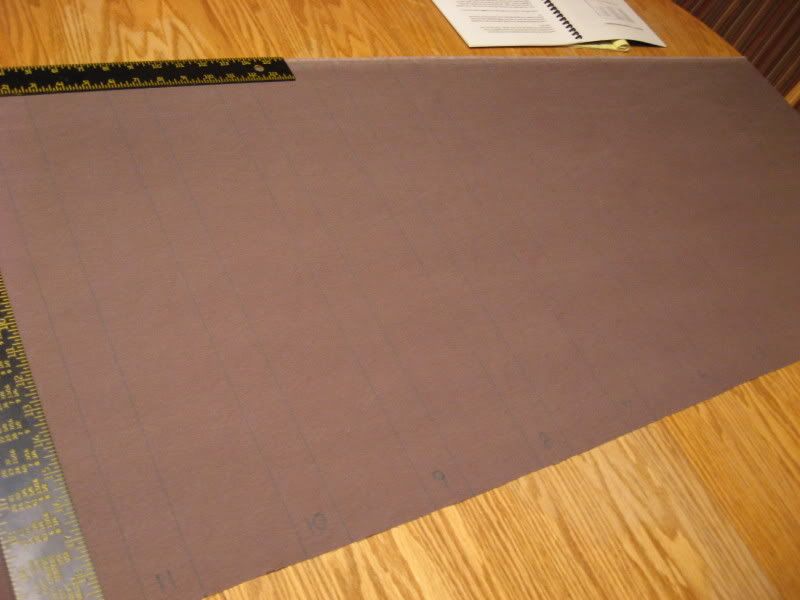

Everything is laid out with the exception of the inner folds for the box pleats. I figured I'd do them after getting the main pleats out of the way. Being the ARB (anal retentive ba**ard) that I am, I couldn't use chalk becuase the marks seemed too thick. So I got a washable fabric marker. Ok, so it kind of sucks using it on this cotton stuff, but it'll do for now.

Getting ready to start making lines.

.

.

.

Measured the length and tried to cut a straight line.

.

.

.

Starting to layout my pleats. I don't have a pic of the final number, but since Alan seemed to stress making your kilt, your kilt and as unique as you want, I went with narrow 1 1/2" pleats. 16 of them to be exact. I love the look of lots of pleats, so well see how this works out. Here's another microbrew for you as well Alan.

.

.

.

.

The pleats are done with the exception of the under folds, so I decided to take a quick break and cut the under apron strip.

.

.

.

That's it for tonight, it's been a long busy weekend, I'll get back to it in a day or so.

Na Zdrowie!!!

-

-

Originally Posted by RK-REX

[SIZE="5"]...Hey, wait a minute, I'm 36... Damn good year for a sewing machine....

Yes, 36 IS a good age  ! !

Originally Posted by RK-REX

...

Measured the length and tried to cut a straight line.

...I went with narrow 1 1/2" pleats....

...cut the under apron strip....

I find that I cannot cut a straight line-try ripping-makes things perfectly straight!

What's the size of the inner pleats? 3 1/2"?

Looking like you will be wearing that in a few more days!

Be well,

-

-

Fair Lady. It must be your elder sister of which you speak, for surely you're not even the half of a decade near such an age.

The inner pleats are 3" as I thought I'd keep the actual pleat design simple at least for my first Xkilt. This was on Alan's advice and since he's the master and I the student. Methinks I should listen.

Oh, I've got lot's of irons in the fire these days, it'll be at least a week and a half, I'd guess.

-

-

I'm going to be interested to see how this looks with the smaller box pleats.

I'm at least 2 kilts away from making MY X-Kilt and I'm running through how I'll make it a bit differently from the instructions, already! All I know is that it'll be in digital camouflage, thanks to way2fractious!

-

-

Hmmmm, I may have some material or machine issues here... Going to research it more today.

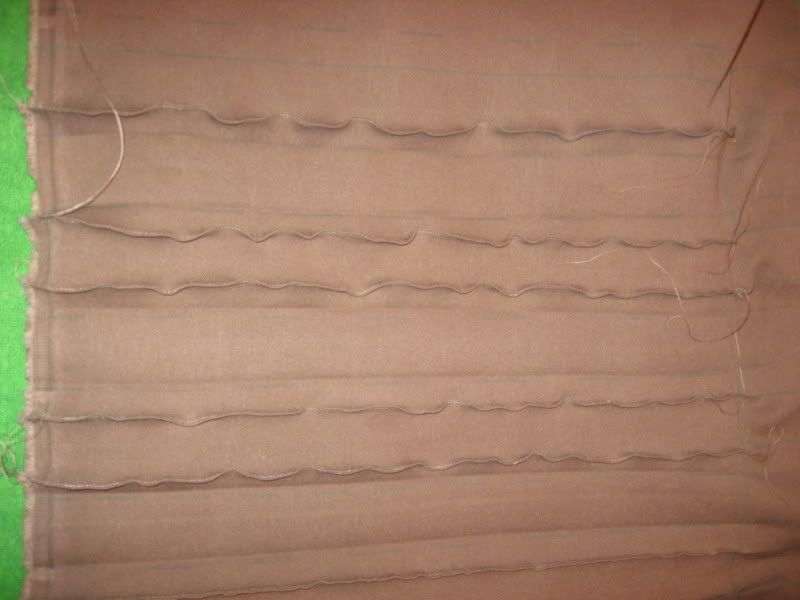

Anyhow, last night I marked the under pleat folds and started sewing the edges of the outer pleats. I'm not sure why this is happening, but I figured I'd research it today and only have a few to tear out if it's a machine issue.

I started by just doing a few without pressing them and I couldn't keep them straight, so out came the iron. After the sewing I hit them again with the iron and they look ok I guess.

.

.

.

After sewing/before second pressing. Is this normal????

.

.

.

Some of them will be ripped out and done over, but once they're pressed they look ok.

.

.

.

I didn't want to get too far into the sewing only to realize I have to rip them all, so I spent the rest of the night pressing and folding and pressing and folding and.... I did learn that if you're using something as an under surface for your pressing, don't use a heavy towel. It "holds" onto the fabric and makes folding a pain. Next time I'll use a piece of masonite or something that is slippery. What say you on the smaller pleats AH?

.

.

.

I'm off to figure out if my fabric puckering (that's a term I've never used before in my life) is the fabric or a machine problem.

-

-

I'm guessing there's a mismatch in the bobbin tension and the upper-thread tension on your machine. Try adjusting the upper-thread tension and sew a few lines of stitching on some scraps. It also could be to some 'stickiness" of the fabric so that the needle/thread don't pass through smoothly.

That puckering is not normal. If the ironing takes it out and it stays out, then no worries.

The smaller box pleats look good!!!

-

-

Agreement on the smaller boxes. Might have to box the pinstripe wool I got the other day.

CT - continue on, try a Melborn Bros while you're at it

-

-

Originally Posted by Alan H

I'm guessing there's a mismatch in the bobbin tension and the upper-thread tension on your machine. Try adjusting the upper-thread tension and sew a few lines of stitching on some scraps. It also could be to some 'stickiness" of the fabric so that the needle/thread don't pass through smoothly.

That puckering is not normal. If the ironing takes it out and it stays out, then no worries.

The smaller box pleats look good!!!

I've done a bit of research today and it's one of three things from what I've read in order from most to least likely.

-Upper thread tension too tight.

-Stitches to short for this fabric.

-Characteristic of the fabric. (unlikely)

Going to mess with the settings and start ripping if I get a chance tonight. I've got a meeting to attend this evening, so I may not get to it until tomorrow. Well, maybe when I get home if it's not too late, I'll experiment with the thread tension.

-

-

Your stitches look very small. I'd suggest adjusting the tension and reducing the number of stitches per inch. The pleat edges aren't taking any significant strain, so you don't need to pack the stitches too tighty.

Also, you'll save time by not trying to mark the edges and following the marks. When sewing pleat edges I keep the edge of the pleat even with the edge of the machine's foot. That spaces the stitch line just the right distance from the edge of the pleat. If your foot is too wide, use a sharpie and mark the right spot on the foot. With practice you can zoom right along, and the stitch lines will be straighter if you speed up. This will save you loads of time and produce a better-looking job.

Kilted Teacher and Wilderness Ranger and proud member of Clan Donald, USA

Happy patron of Jack of the Wood Celtic Pub and Highland Brewery in beautiful, walkable, and very kilt-friendly Asheville, NC.

New home of Sierra Nevada AND New Belgium breweries!

-

-

FINAL SCORE:

Rikk & his X-kilt: 0

Walmart fabric of unknown thread content: 1

I spent a good two hours playing around tonight, tried everything possible. Upper and lower tensions, new needle, different size needle, stitch length, foot pressure.....no dice. Pucker, pucker, pucker. So I had some fabric of a similar weight that I'd used to make some flashes with. Folded it over, set all the settings back to "normal" ran a line of stitches down each side of a faux box pleat. Perfectly straight. (Insert lots of vulgarity and profanity here!)

I'm going to venture up to Joann's tomorrow night and buy something decent to sew start over on. At least I'll be a bit more experienced at the calculations and the layout. Once I'm back to the sewing part, I'll pick back up with this thread.

Be warned, before you take the time to layout and start sewing your X-kilt out of an unknown, cheap fabric, buy a sample of the fabric and try sewing it first. It may be like my "EX"-kilt fabric and have a mind of it's own.

-

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

|